Whole Genome Sequencing & Metagenomics

Whole Genome Sequencing & Metagenomics

Purchased in August 2022, our Illumina MiSeq goes above and beyond in the identification of pathogens. Are you working with a persistent microorganism at your site and want to identify it to strain level? Do you want to identify if the Listeria monocytogenes isolated in low care is the same as the one isolated in goods in? Want to show that a particular disinfection method can overcome drug and biocide resistance genes? We can provide the full genetic background to most bacterial isolates and help to remediate. Please get in touch with us to discuss your requirements.

Biofilms

Biofilms

Employing the gold standard in biofilm formation techniques, we have a modified CDC reactor allowing for the production and maintenance of a wide range of biofilms. Here we can replicate waste water facilities, manufacturing environments and other applications to demonstrate the effectiveness of ozone related systems on biofilm prevention and reduction.

Aqueous Ozone

Aqueous Ozone

Our aqueous system is linked to another 10 g generator (Ozone Industries UK) and equipped with both redox and dissolved ozone sensors (ATI, UK) allowing for accurate ozone measurements for a wide range of applications. We can help to validate food product washing, disinfection rinsing, surface disinfection and more.

Other Disinfection Technologies

Other Disinfection Technologies

The chamber can be modified to allow for the analysis of other disinfection technologies such as UV and free radical production. Please get in touch with us to discuss your requirements.

Aerosolization

Aerosolization

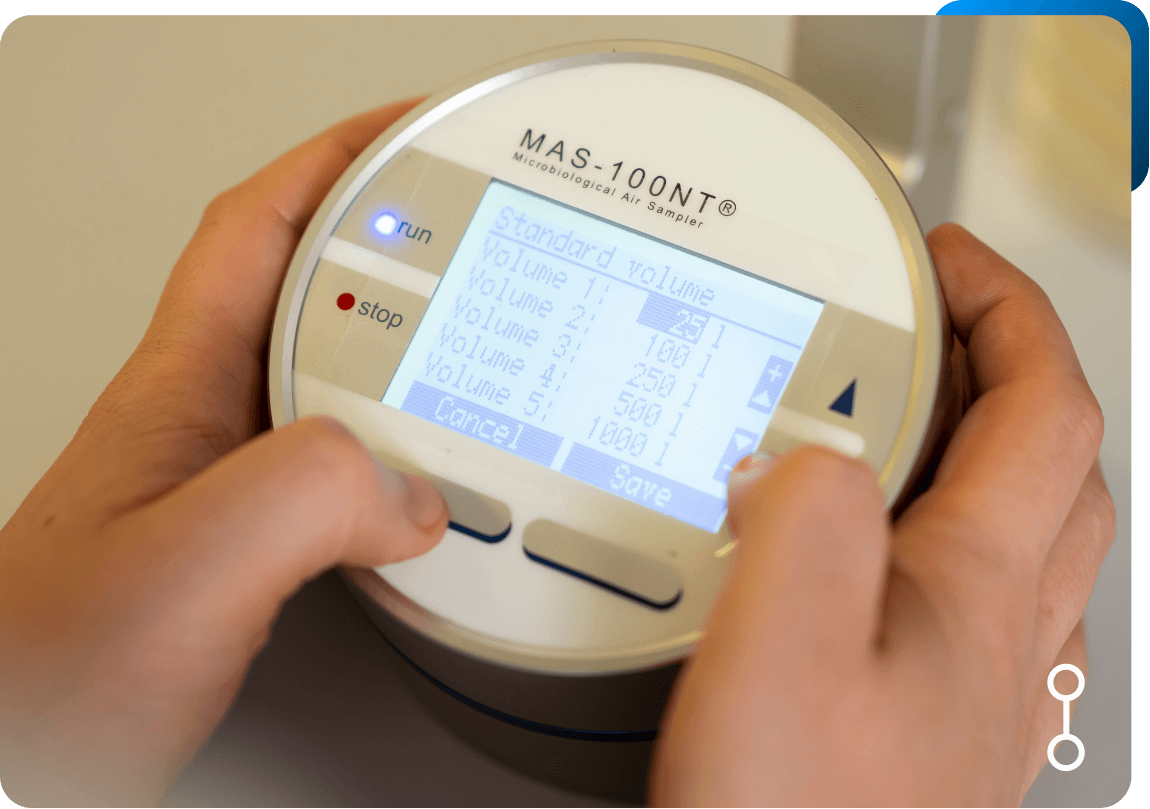

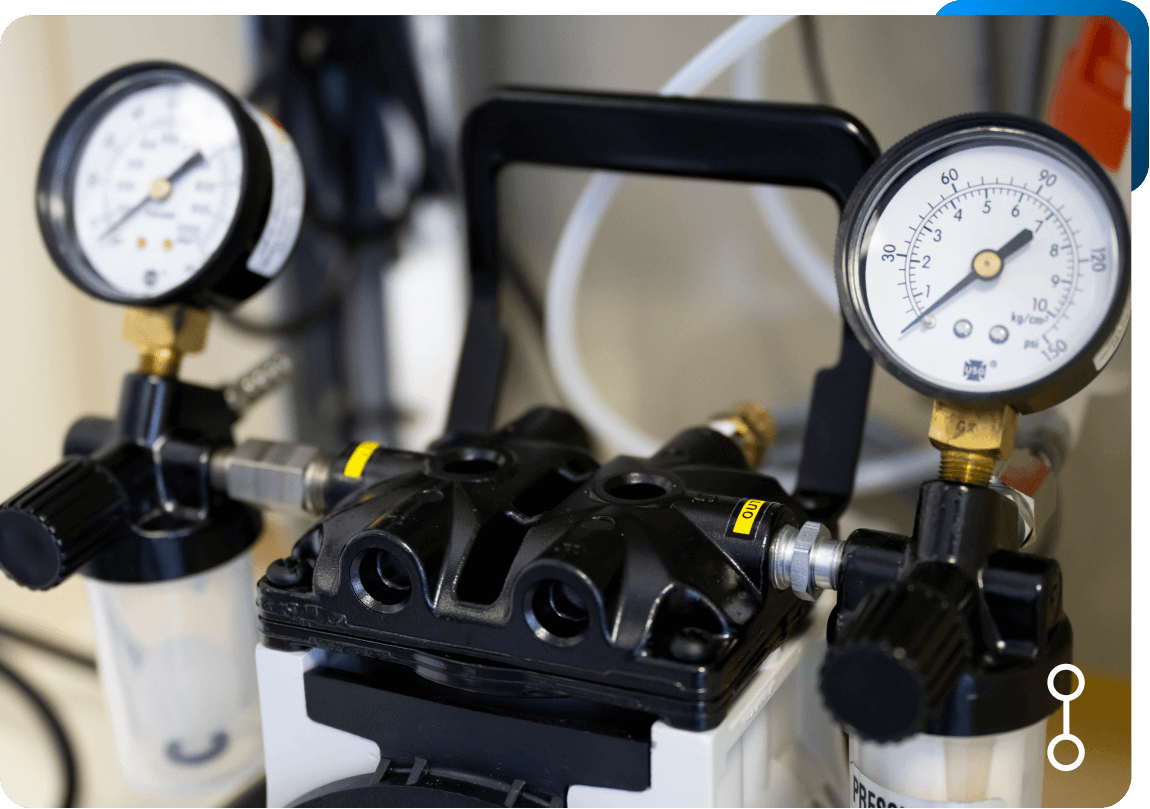

The chamber is capable of aerosolising a wide range of human pathogens. For such studies we employ a 24 Jet Collison nebuliser (Acoem, UK) linked to a Welch WOB-L piston Vacum pump to ensure reliable microorganism aerosolization. Microorganisms are sampled using a MAS-100 NT® autosampler that can be positioned in multiple areas with variable air sample volumes at set time points. Samples are collected directly onto growth media so that accurate numbers of recovered microorganisms can be reported.

Bioaerosol Chamber

Bioaerosol Chamber Details

- One of its kind in Wales and only a handful of such facilities across the UK, our bioaerosol chamber is purpose built for ozone analysis.

- Constructed of polypropylene and measuring approximately 21 m3, the walk-in facility allows for large scale decontamination experiments.

- Feed via a 10 g ozone generator (Ozone Industries, UK) and monitored via a UKAS calibrated 2B tech 106-M monitor, ozone can be generated in situ or via your own device with the assurance that the concentration is measured, logged and accurate.

- The chamber has a number of fans ensuring even distribution of gaseous ozone and aerosolised microorganisms.

- Equipped with humidity controls and the ability to test at certain temperatures, a wide range of environmental conditions can be replicated. Using the internal VOC monitor, particulates formed can also be measured and reported, linking with MCBA consultants we can offer a more detailed analysis of by product formation using an onsite Thermal Desorption, Gas Chromatography-Mass Spectrometer (TD-GCMS).

An upgraded extraction system, completed in May 2023, allows for fast and efficient aerosol extraction equating to up to 25 air changes per hour and allowing ozone concentrations to be reduced from 50 ppm to 0.01 ppm within 25 minutes, important within specific applications.

All of our surface decontamination testing follows, as closely as possible, BS EN 17272, allowing companies to utilise our services to undertake research and development on their devices prior to submitting data to a regulator for Biocide Product Regulation (BPR) approval.

Bioaerosol Chamber details

- One of its kind in Wales and only a handful of such facilities across the UK, our bioaerosol chamber is purpose built for ozone analysis.

- Constructed of polypropylene and measuring approximately 21 m3, the walk-in facility allows for large scale decontamination experiments.

- Feed via a 10 g ozone generator (Ozone Industries, UK) and monitored via a UKAS calibrated 2B tech 106-M monitor, ozone can be generated in situ or via your own device with the assurance that the concentration is measured, logged and accurate.

- The chamber has a number of fans ensuring even distribution of gaseous ozone and aerosolised microorganisms.

- Equipped with humidity controls and the ability to test at certain temperatures, a wide range of environmental conditions can be replicated. Using the internal VOC monitor, particulates formed can also be measured and reported, linking with MCBA consultants we can offer a more detailed analysis of by product formation using an onsite Thermal Desorption, Gas Chromatography-Mass Spectrometer (TD-GCMS).

An upgraded extraction system, completed in May 2023, allows for fast and efficient aerosol extraction equating to up to 25 air changes per hour and allowing ozone concentrations to be reduced from 50 ppm to 0.01 ppm within 25 minutes, important within specific applications.

All of our surface decontamination testing follows, as closely as possible, BS EN 17272, allowing companies to utilise our services to undertake research and development on their devices prior to submitting data to a regulator for Biocide Product Regulation (BPR) approval.

Bioaerosol Chamber details

- One of its kind in Wales and only a handful of such facilities across the UK, our bioaerosol chamber is purpose built for ozone analysis.

- Constructed of polypropylene and measuring approximately 21 m3, the walk-in facility allows for large scale decontamination experiments.

- Feed via a 10 g ozone generator (Ozone Industries, UK) and monitored via a UKAS calibrated 2B tech 106-M monitor, ozone can be generated in situ or via your own device with the assurance that the concentration is measured, logged and accurate.

- The chamber has a number of fans ensuring even distribution of gaseous ozone and aerosolised microorganisms.

- Equipped with humidity controls and the ability to test at certain temperatures, a wide range of environmental conditions can be replicated. Using the internal VOC monitor, particulates formed can also be measured and reported, linking with MCBA consultants we can offer a more detailed analysis of by product formation using an onsite Thermal Desorption, Gas Chromatography-Mass Spectrometer (TD-GCMS).

An upgraded extraction system, completed in May 2023, allows for fast and efficient aerosol extraction equating to up to 25 air changes per hour and allowing ozone concentrations to be reduced from 50 ppm to 0.01 ppm within 25 minutes, important within specific applications.

All of our surface decontamination testing follows, as closely as possible, BS EN 17272, allowing companies to utilise our services to undertake research and development on their devices prior to submitting data to a regulator for Biocide Product Regulation (BPR) approval.